DEEP LEARNING

INSPECTION

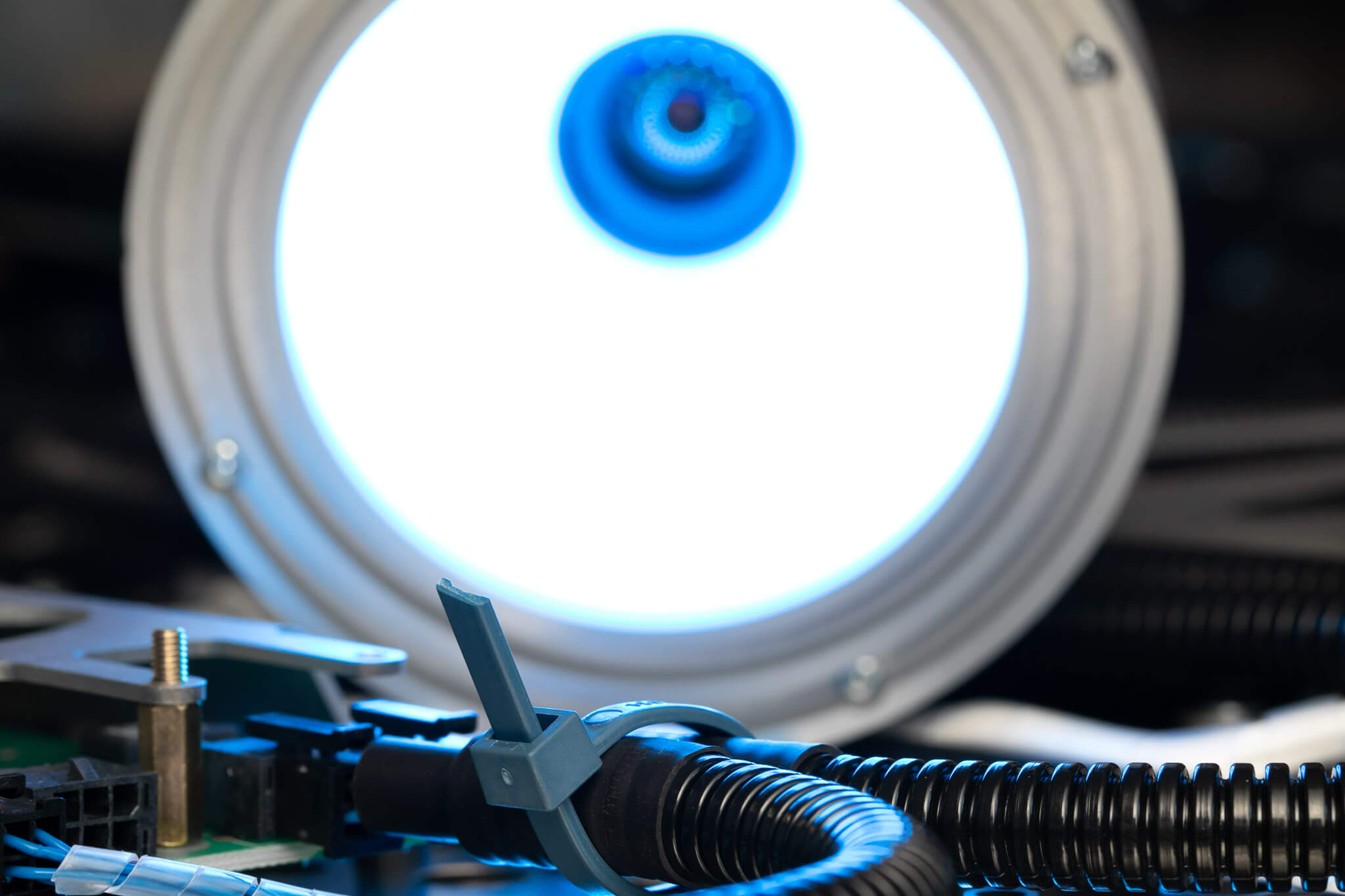

Intelligent quality inspection of complex assemblies with multiple assessment parameters.

The challenge

- Different test specimens and situations

- More than 50 different test parameters

- Multiple possibilities for approved parts

- No clear definition of failed parts

- 100% automatic testing needed

DEEP LEARNING

INSPECTION

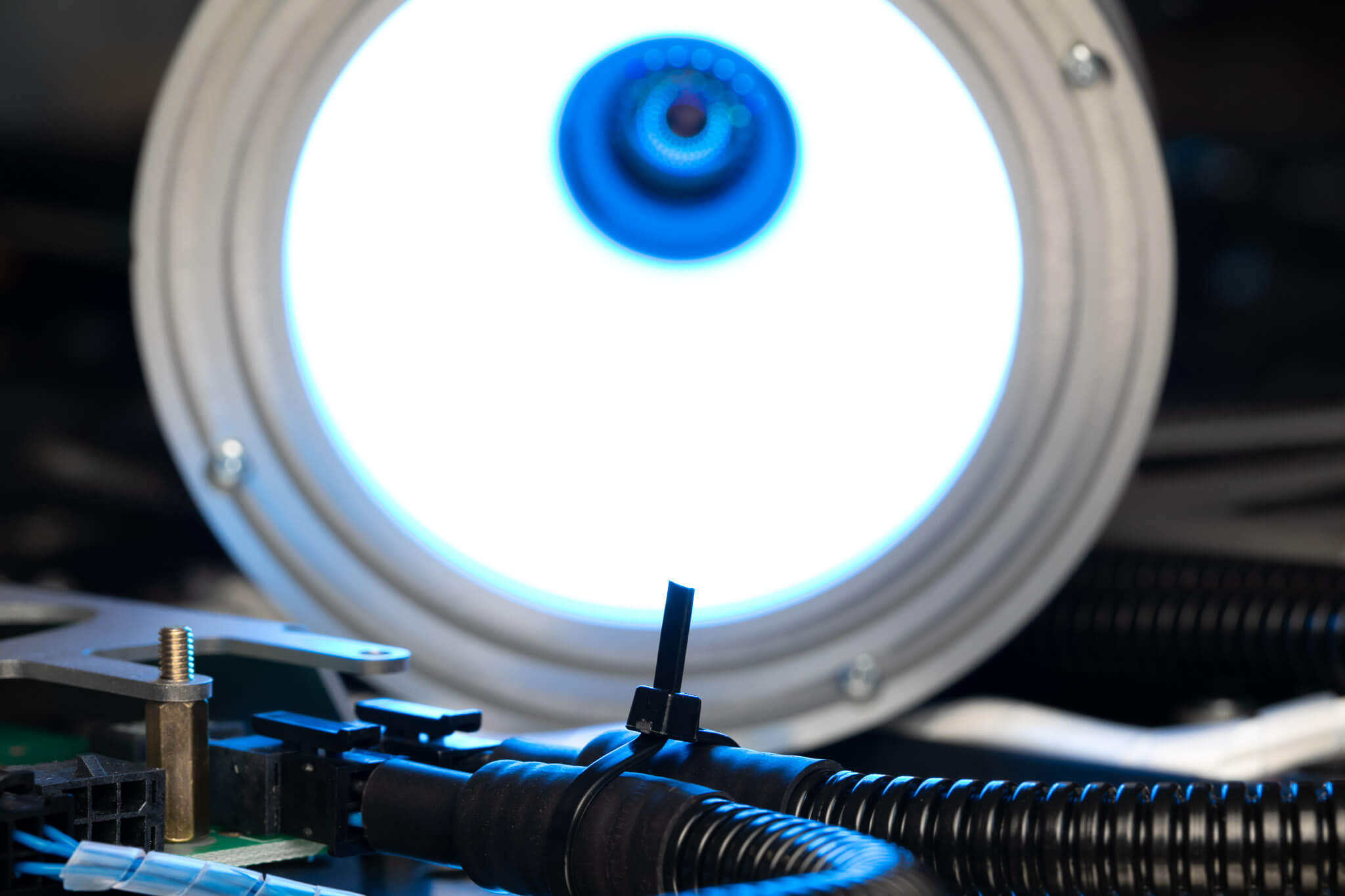

Intelligent quality inspection of complex assemblies with multiple assessment parameters.

The challenge

- Different test specimens and situations

- More than 50 different test parameters

- Multiple possibilities for approved parts

- No clear definition of failed parts

- 100% automatic testing needed

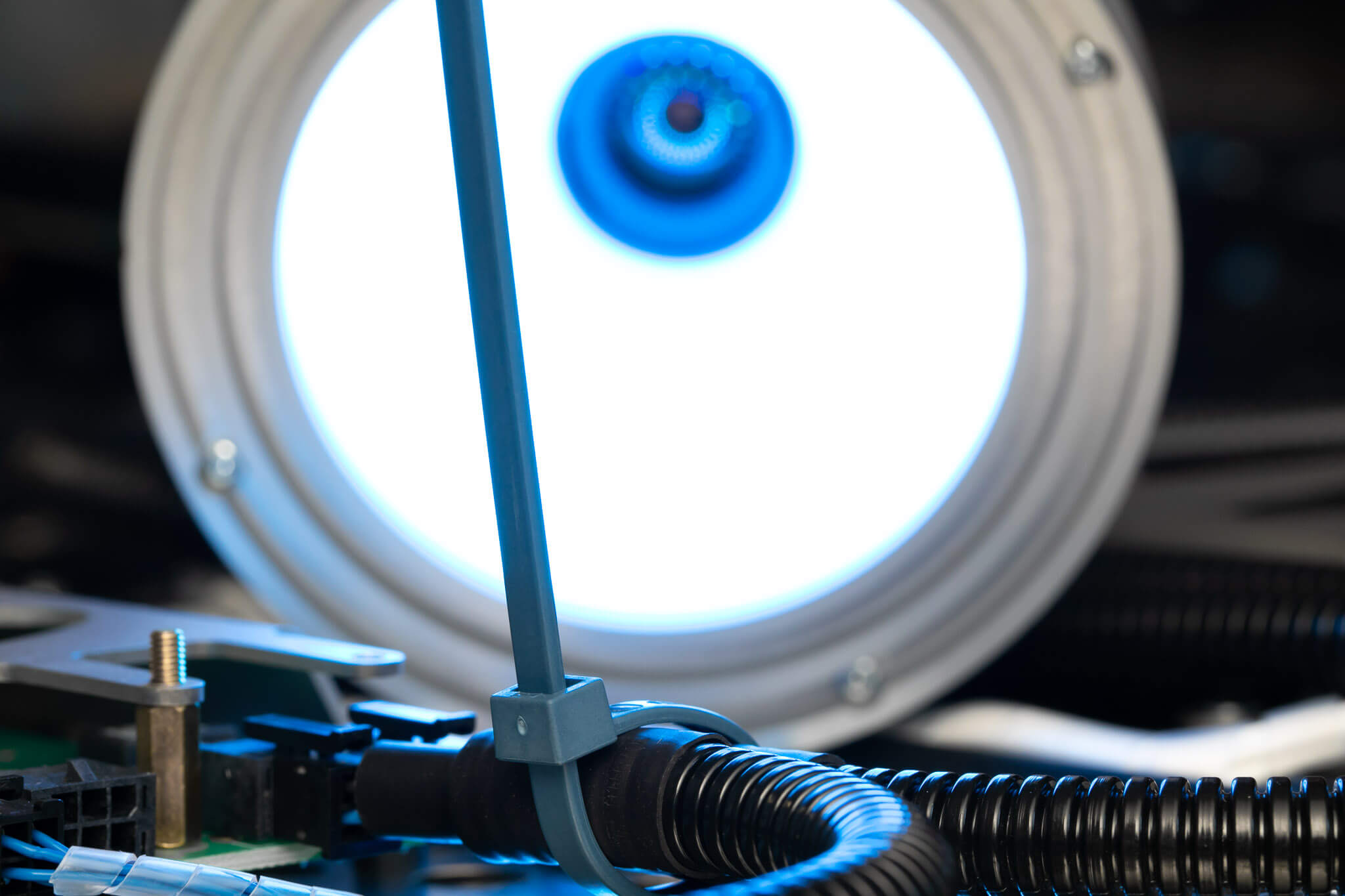

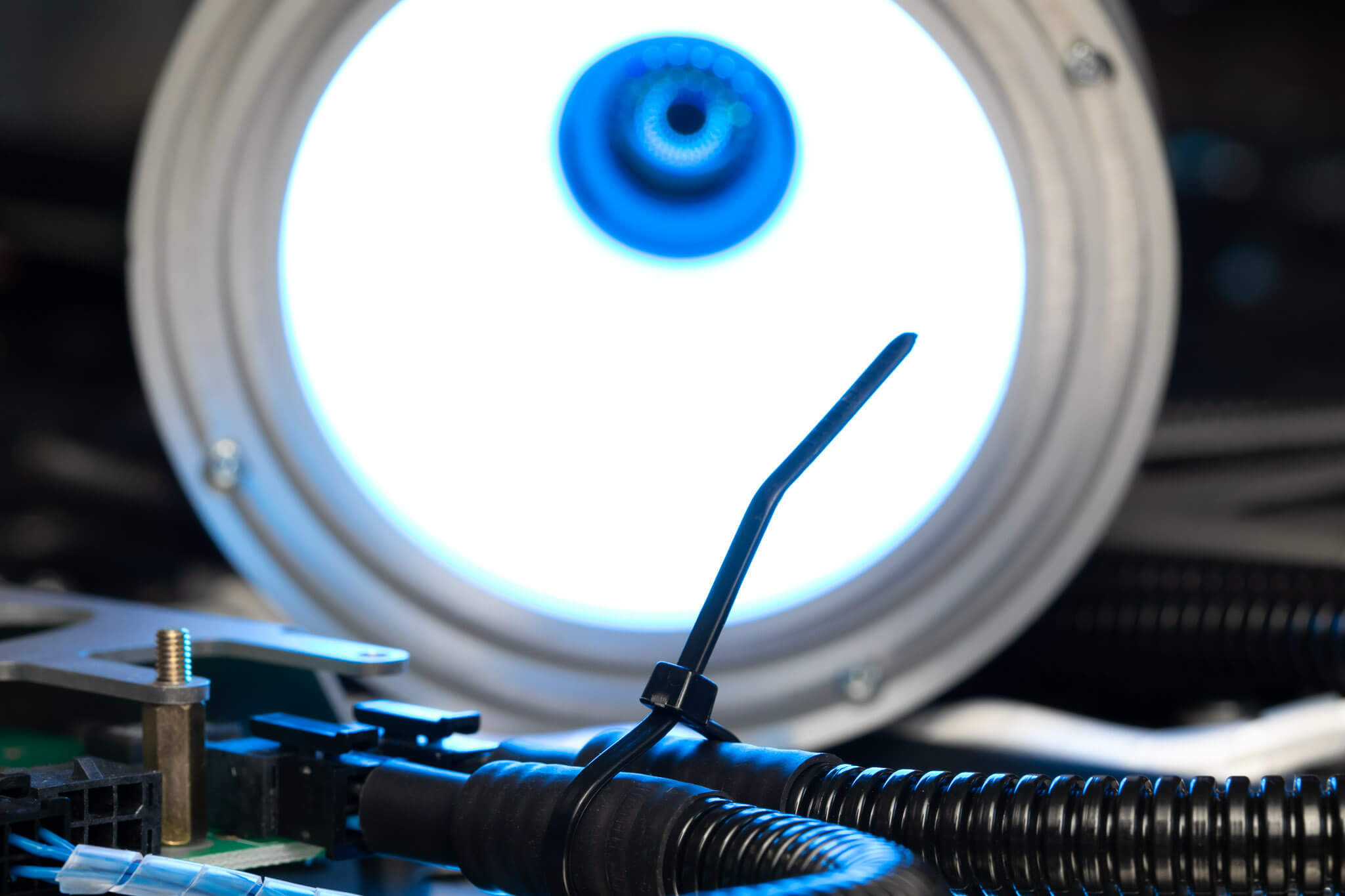

The situation

- Complicated components consisting of numerous, delicate parts

- Many features are fitted manually, resulting in numerous possible sources of error

- Quality inspection is tiring because it can only be done by the human eye

- Not precise, exhausting

The result

- Hand-Eye application with an articulated arm robot and camera system

- Camera system uses AI (Artificial Intelligence)

- User-friendly interface simplifies the AI Deep Learning training process

The situation

- Complicated components consisting of numerous, delicate parts

- Many features are fitted manually, resulting in numerous possible sources of error

- Quality inspection is tiring because it can only be done by the human eye

- Not precise, exhausting

The result

- Hand-Eye application with an articulated arm robot and camera system

- Camera system uses AI (Artificial Intelligence)

- User-friendly interface simplifies the AI Deep Learning training process

EDMUND

JENNER-BRAUNSCHMIED

Expert for

industrial image processing,

electronics & software

EDMUND

JENNER-BRAUNSCHMIED

Expert for

industrial image processing,

electronics & software

Every successful project has a beginning

At Nordfels there is always a competent contact person available to discuss solutions to every problem.