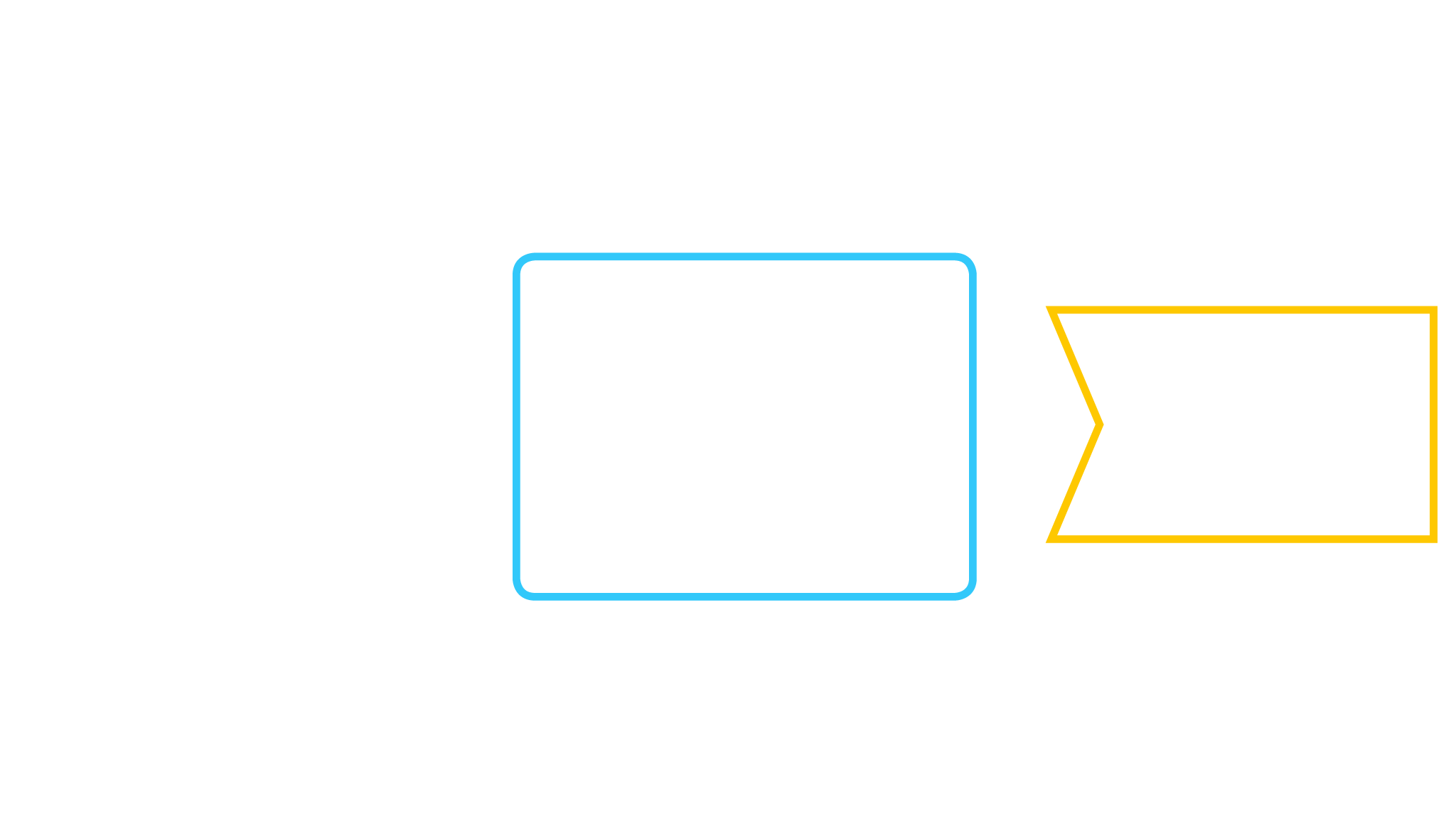

Handling

Laser

Packaging

Cell

Single round cells from various premium segments

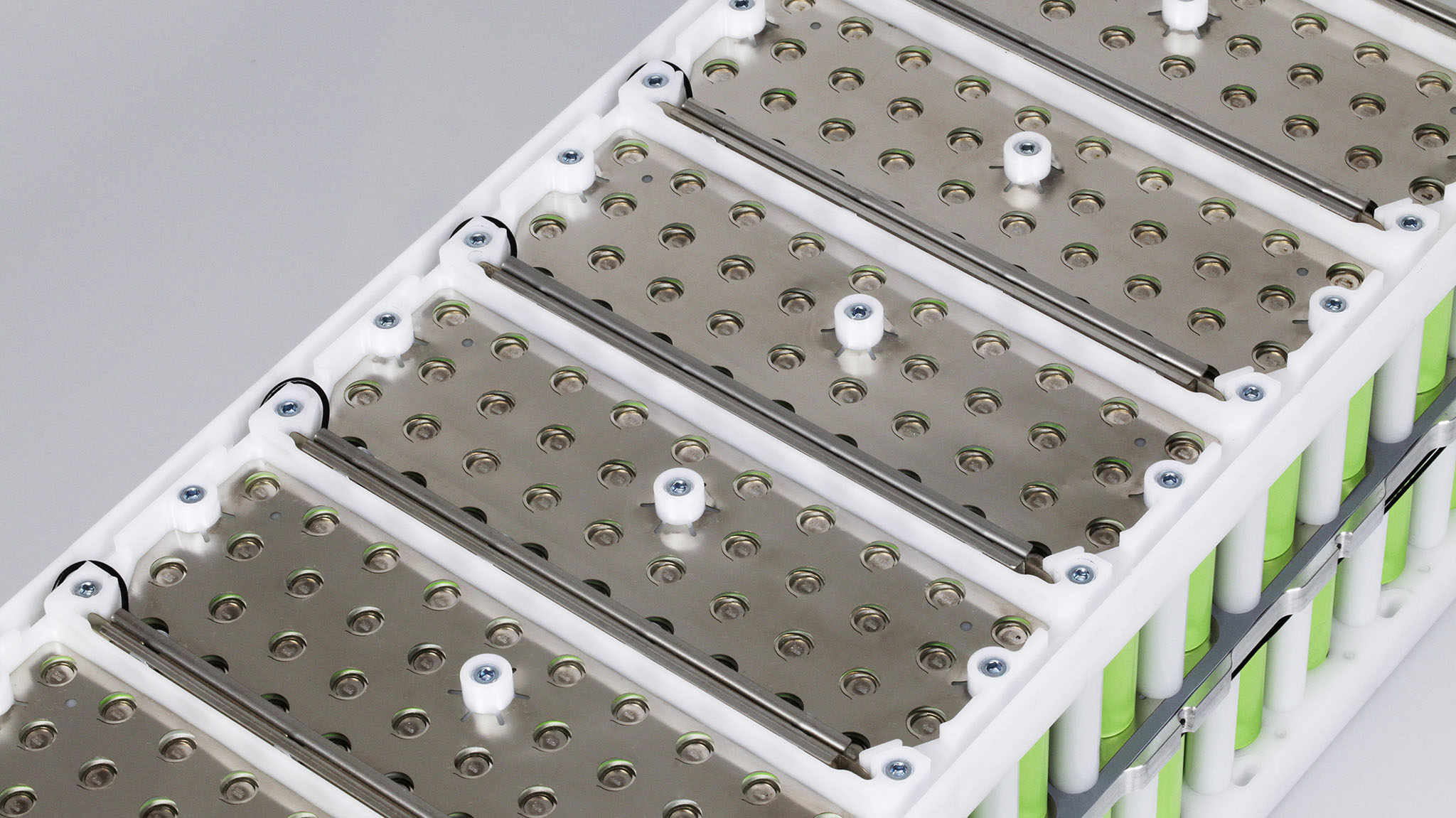

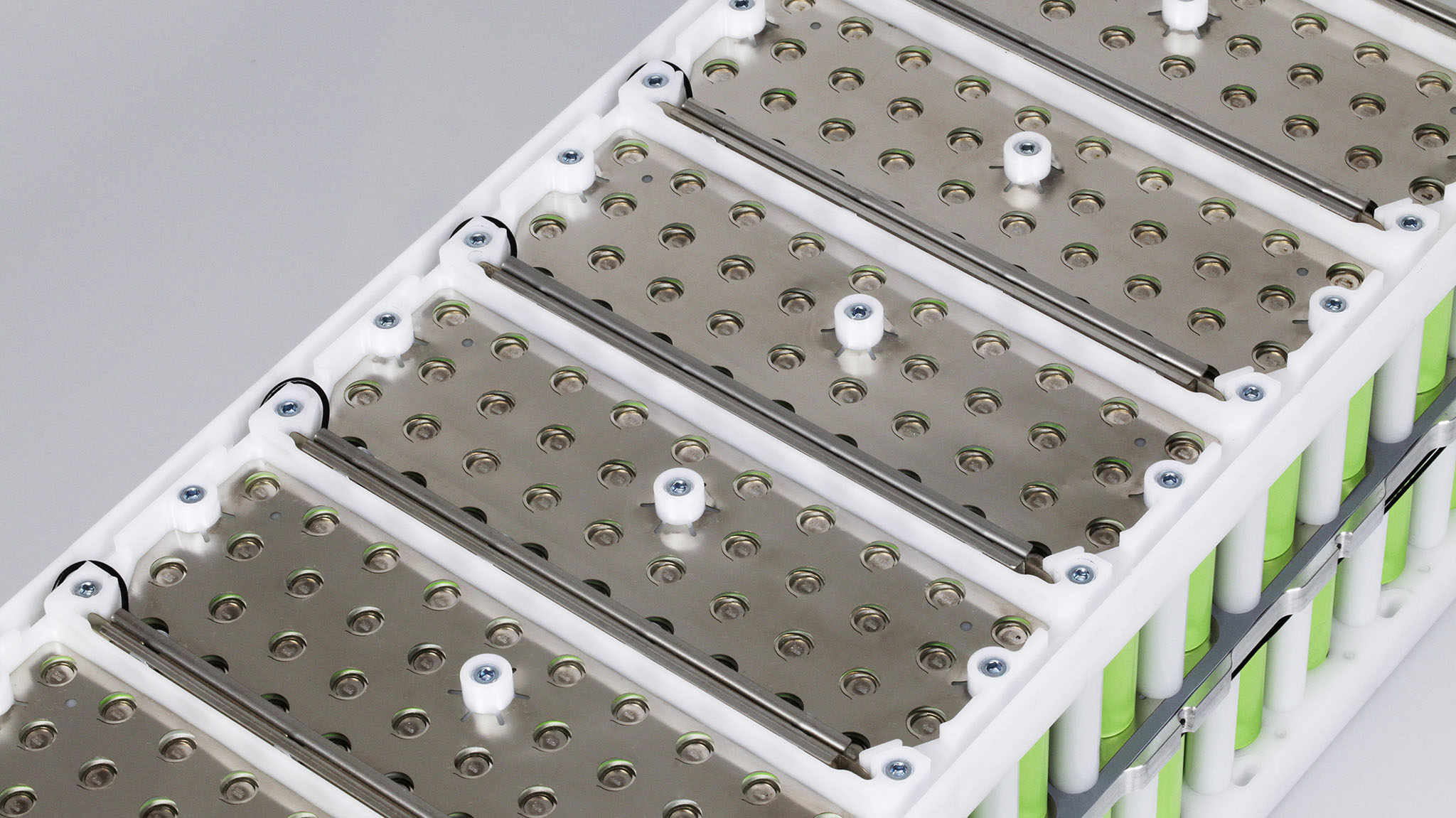

Macro Cell

High-quality parallel group in precision laser-welded bond

Battery pack

Ready-to-use round cell batteries, with patented temperature management as required

Handling

Fully automated with highest cycle rates and integrated simultaneous quality assurance. The first process step in the Voltjet system involves measuring the impedance of each individual cell as they arrive to determine their quality. This is followed by pre-assembling the macro cells prior to welding.

Laser

At the heart of the Voltjet system, the individual cells are welded together on both the positive and negative sides using laser welding technology that has been tried and tested over many years. Excellent, homogeneous laser welded joints, unmatched process speed and highest quality.

Packaging

Automation solutions for the completion of battery packs are implemented based on individual customer requirements. Always adapted to the customer’s specifications and fully integrated into their production process.

Adaptable and reliable

From the fully automated complete system through to individual work stations to improve the assembly process. Nordfels offers perfect results from the macro cell to the finished battery pack.

VOLTJET

First fully integrated, automated battery pack production line VJ 1702

Nordfels was the first company in the world to connect lithium-ion cells reliably and ready for use using high-precision laser welding technology. The first fully integrated production line for high-quality lithium-ion batteries has now been created in continuous further development together with state-of-the-art automation technology and robotics: VOLTJET 1702

Handling

Laser

Packaging

Cell

Single round cells from various premium segments

Macro cell

High-quality parallel group in precision laser-welded bond

Battery pack

Ready-to-use round cell batteries, with patented temperature management as required

Handling

Fully automated with highest cycle rates and integrated simultaneous quality assurance. The first process step in the Voltjet system involves measuring the impedance of each individual cell as they arrive to determine their quality. This is followed by pre-assembling the macro cells prior to welding

Laser

At the heart of the Voltjet system, the individual cells are welded together on both the positive and negative sides using laser welding technology that has been tried and tested over many years. Excellent, homogeneous laser welded joints, unmatched process speed and highest quality.

Packaging

Automation solutions for the completion of battery packs are implemented based on individual customer requirements. Always adapted to the customer’s specifications and fully integrated into their production process.

Adaptable and reliable

From the fully automated complete system through to individual work stations to improve the assembly process. Nordfels offers perfect results from the macro cell to the finished battery pack.

Voltlabor – Nordfels partner

As a successful partner of Nordfels, Voltlabor continuously supplies know-how and comprehensive support in all aspects of efficient round cell battery systems.

Voltlabor – Nordfels partner

As a successful partner of Nordfels, Voltlabor continuously supplies know-how and comprehensive support in all aspects of efficient round cell battery systems.

MARTIN

REINGRUBER

Specialist for

mechanical engineering and

battery production technology

MARTIN

REINGRUBER

Specialist for

mechanical engineering and

battery production technology

Every successful project has a beginning

At Nordfels there is always a competent contact person available to discuss solutions to every problem.